Key takeaways:

- Every Minted holiday card is the result of a collaboration between independent artists from around the world, community voters, and expert curators.

- Premium materials, advanced printing techniques, and rigorous quality checks at every stage guarantee that your holiday card feels as special and meaningful as the message it carries.

- Personalization and innovative technology make it easy to create cards that reflect your story.

There’s something magical about holding a holiday card that feels just right—the shimmer of foil catching the light, the weight of the paper, the way the design elements complement your family photo. At Minted, that magic doesn’t happen by chance. It begins with independent artists who pour their creativity into fresh designs and continues through months of planning, craftsmanship, and meticulous checks. Every step is driven by one goal: to deliver a card that looks and feels as thoughtful as the message inside.

From artist concept to your mailbox, each Minted holiday card tells a story of care and collaboration. Take a look behind the scenes to see how your card comes to life—and why so many trust Minted to help share their holiday wishes.

How Our Holiday Card Designs Are Chosen

Minted’s core belief is simple: good design can be found anywhere. That’s why we crowdsource. Every year, we run multiple Holiday Card Challenges where independent artists around the world are invited to submit their work. The Minted community—including artists and customers—votes in a blind process so ideas rise on merit, not name. Top‑ranked winners come together with our Editors’ Picks to shape a collection that balances trends and timelessness. Planning begins nearly a year in advance, allowing us to refine, curate, and ensure every detail is right.

Once our holiday card designs for the year are chosen, artists send us digital files, including the front and back of the card, the coordinating envelope and liner, and multiple colorways. The Minted team tailors each file to our customization tools, then runs multiple rounds of audits to confirm layout, legibility, and functionality.

Making it uniquely yours with personalization

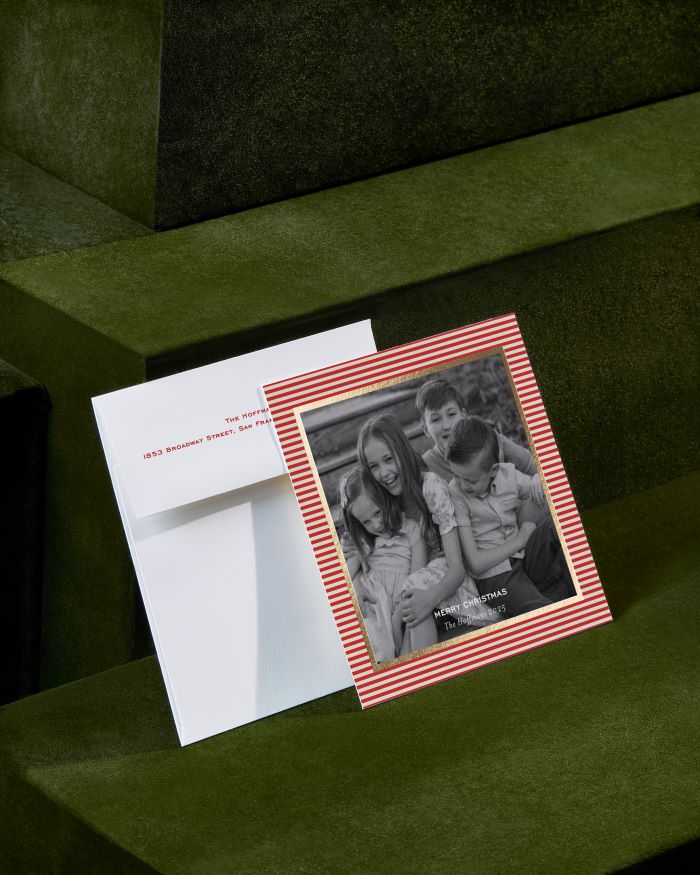

Once you’ve chosen a favorite design, the rest is about making it your own. Choose colors and greetings, add or swap photos, refine fonts and text, pick a back‑of‑card layout, and, if you’d like a hand, submit a custom design request. For most products, you’ll see a final digital proof of your requested changes before you order so that you can make any last adjustments with confidence.

Here are all the ways you can customize your Minted holiday card:

- Design options. Personalize your card using the option to choose elements such as:

- Color

- Greetings & text

- Photos

- Size & format

- Shape

- Back‑of‑card designs and layouts

- Envelopes: Pick from 15 envelope colors, add matching or coordinating liners, and opt for white‑ink addressing on dark stocks.

- Proof & approval: Review a live preview as you edit and then a final proof (if available on your chosen design) reflecting your requested changes.

- Addresses: Apply free, unlimited recipient addressing in coordinated styles; manage contacts in Address Book and add return address printing.

The journey from order to doorstep

The moment you place your order, something pretty amazing happens behind the scenes. Your holiday card design begins a journey through our trusted manufacturing partners, where each step brings your vision closer to reality.

- Passed to manufacturing partners. Your order is routed to specialized facilities that handle printing, cutting, and finishing.

- Card finishing stages. Based on your selections, cards may be die‑cut, duplexed for extra thickness, foil‑pressed, letterpress‑printed, or photo‑mounted.

- Parallel envelope printing & staging. Envelopes are printed at the same time and staged for efficient consolidation with your finished cards.

- QC and accuracy checks before shipping. We verify quality and order accuracy, then package everything for safe delivery.

The art of the press

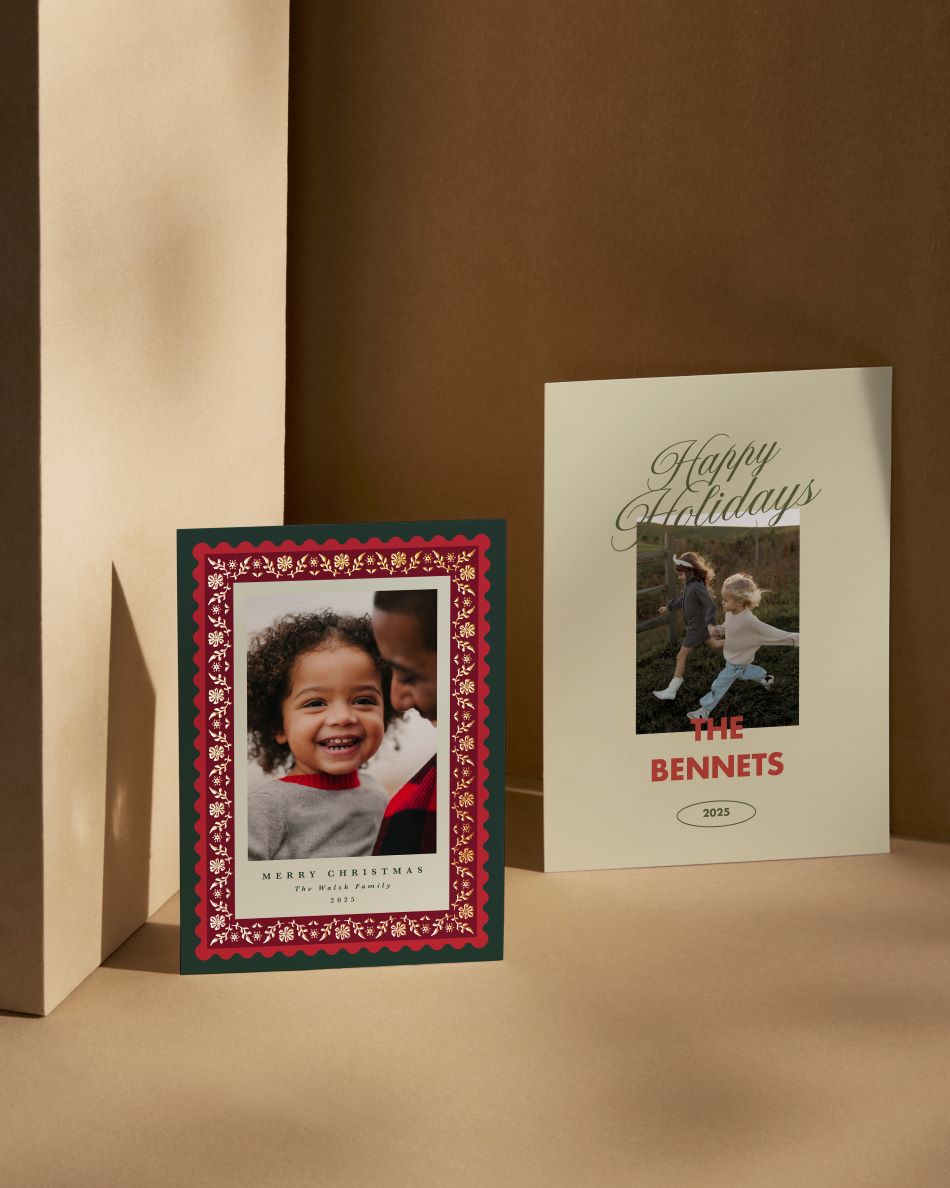

Once you’ve personalized your holiday card design and submitted your order, production brings it to life with printing techniques chosen to ensure your card looks and feels as beautiful as possible. The specific product choices you make—such as design, finish, and paper—determine which printing technique is used for your order.

- Digital printing delivers vibrant, full‑color reproduction, ideal for photo‑forward designs and fine detail.

- Foil-pressed cards go through the real foil press to transfer metallic foil with heated dies for a clean, reflective finish you can see and feel.

- Custom letterpress creates deep, tactile impressions in thick cotton stock; each ink color runs as its own pass.

- Photo Mount™ adds a subtle dimension by hand‑mounting a semi-gloss photograph print to the card.

- Specialized envelope printing. Full‑color (CMYK) and white‑ink printing on colored envelopes provides high contrast and clear readability.

After printing, each order undergoes specialized finishing stages, depending on the product type, including die-cutting, duplexing, foiling, letterpressing, or photo-mounting, and is quality-controlled at every step. At the same time, envelopes are printed and staged for shipping.

Once both are ready, they’re consolidated at shipping, undergo a final round of quality and accuracy checks, and are carefully packaged for delivery.

Quality at every step: Our gold standard

From the moment your order enters the system to when your cards arrive at your door, several quality checks happen behind the scenes to make sure everything turns out just right.

Manufacturing teams conduct quality checks at every production step:

- Quality checks at every stage. Operators inspect printing, cutting, foiling, finishing, consolidation, and pack‑out to catch issues early.

- Expert operators maintain standards. Specialists run each process using Minted’s documented quality criteria for consistent results.

- Weekly feedback drives improvement. Facilities share data and learnings every week to keep raising the bar across the network.

- Minted‑specific color SOPs on every press. Standardized color workflows keep prints accurate and reliable throughout the season.

- Barcode system ensures order accuracy. Barcode‑based consolidation designed to verify that the right cards, envelopes, and components ship together.

The continuous improvement process ensures that these standards continue to improve, so each holiday season with Minted is even better than the last.

How your holiday card is made: Frequently asked questions (FAQs)

Now that you've seen the journey from artist's vision to finished card, you probably have some specific questions about how your holiday card is made and what makes each step special. Here are answers to the most common questions about the process and your options along the way.

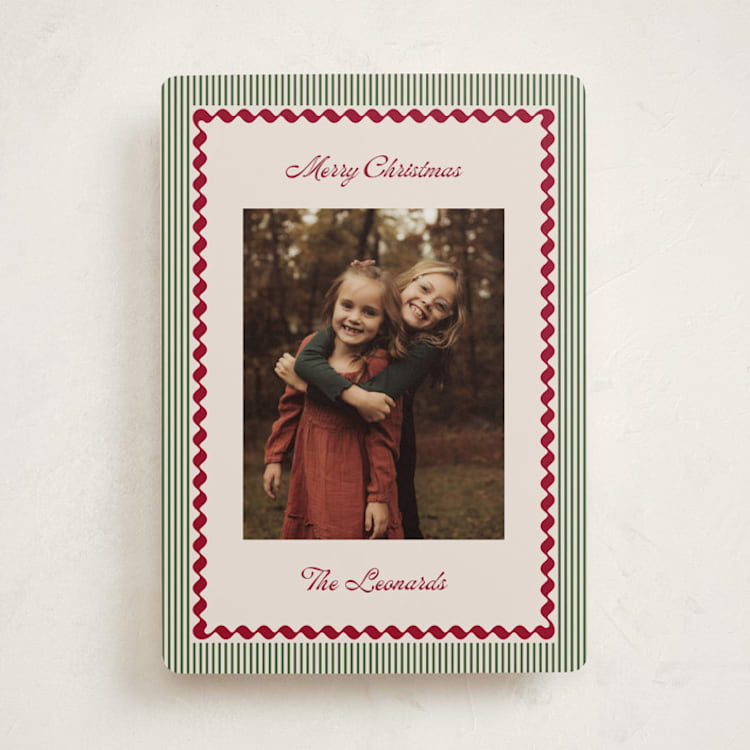

What makes Minted’s paper quality different from other companies?

Minted’s paper quality stands out because each stock is carefully selected for its weight, texture, and finish. You can choose from a range of premium options, including Smooth Signature, Signature, Pearlescent, Recycled, DoubleThick™, TripleThick™, 100% Cotton, and Premium 100% Cotton—many of which are FSC‑certified, post‑consumer recycled, or made from natural fibers.

How do independent artists get their designs selected?

Independent artists get their designs selected through Minted Design Challenges. Designers from around the world submit their work, the community votes in a blind process, and Minted’s editorial team curates the final collection to balance what’s trending with what feels timeless.

What personalization options are available for my cards?

Personalization options include changing colors, shapes, and layouts, adding extra photos or text, and selecting free recipient addressing. You can also shop a wide variety of stationery accessories to complete your holiday look.

What printing techniques are available for different card styles?

Different holiday card styles use different printing techniques depending on the design. Minted offers digital printing, real foil press, custom letterpress, and Photo Mount™ options—each chosen to highlight the tactile and visual qualities of your card.

How do you maintain color accuracy from screen to print?

Minted maintains color accuracy from screen to print by following Minted‑specific color printing SOPs that are installed on every partner press. Each press is required to have these Minted color SOPs in place. Throughout the season, Minted’s team routinely checks customer orders for color accuracy to ensure that printed tones look natural, balanced, and true to life.

What quality checks ensure my holiday cards will look perfect?

Minted checks that your holiday cards look perfect by running multiple quality checks at every stage—from layout and color accuracy to trimming and finishing. Barcode tracking and careful human inspection check that every card in your order meets Minted’s high standards before it’s shipped.

How does Minted handle large order volumes during the peak holiday season?

Minted handles large holiday volumes during peak holiday season by planning nearly a year in advance and scaling production across multiple facilities, including seasonal printing partners, to deliver your order on time.

How far in advance does Minted plan for the holiday season?

Minted begins planning for the holiday season early each year, typically in January. This early start allows time to prepare new artist challenges, review designs, secure materials, and schedule production so everything runs seamlessly.

How long does it take to make a holiday card from order to shipping?

Most holiday card orders take only a few business days to print, finish, and ship. The exact timeline depends on the printing technique and shipping option you choose. Minted plans months ahead and works closely with trusted partners to ensure your order moves smoothly, even during the busy season.

Creating Memorable Holiday Moments

From an artist’s first sketch to your finished card, every Minted holiday card is the result of creativity, care, and craftsmanship. Each one passes through the hands of designers, print specialists, and quality teams who treat your order as if it were their own.

When your cards arrive, they’re more than just paper and ink—they’re a reflection of the time, love, and thought you put into the holiday season. Whether you’re sharing a milestone, a family photo, or a simple holiday greeting, your card carries a bit of that Minted magic with it.